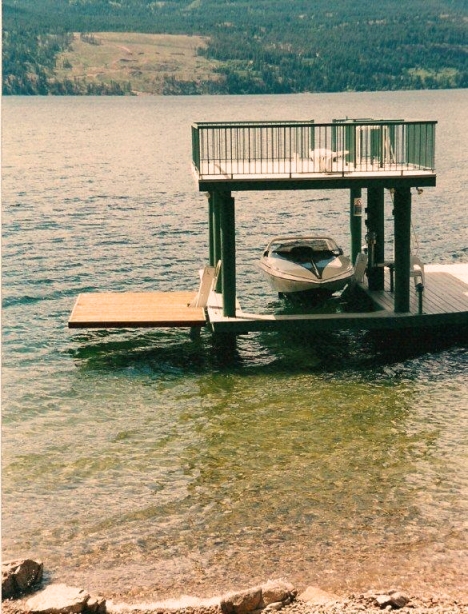

There are a few things that need your full attention when you’re operating your Leisure Boat Lift. When bringing your boat up or down, you need to keep an eye on the lift and its components. The lift is a specially designed piece of machinery that requires your attention. It is important to keep notice of the chain and make sure that it is straight and all of the links are lined up.

Another very important aspect of the lift is to watch out for the height limit – after each install, we draw a line that the lift cannot pass (as shown in the photo below.) If the line fades, you can simply re-draw it on with any thick felt pen. It’s important to watch for this line in any condition. Bad weather can make it a little harder to watch this line, or get everyone in a hurry, but lifting your Leisure Boat Lift above that line causes the chain hook to suck itself into the chain hoist and cause a big problem.

In normal conditions, you don’t even need to lift your boat as high as the line – as long the cradle is out of the water, you’re good to go.

When someone is operating for the first time (that isn’t the owner) it’s a good idea to supervise them and make sure they’re looking out for the chain and the height of the boat. Anyone who is operating the lift should be attentive and listen to the sounds being made by the lift.

If you hear a lot of clunking around, pausing / stopping as you lower the lift, abnormal whining or any other out-of-place sounds coming from the motor, or any other sound that seems irregular, don’t hesitate to give us a call. Sometimes all it takes is some advice from our crew over the phone, and the problem can be solved. Otherwise, don’t hesitate to ask our service crew to come out and fix whatever ails the lifter.

The chain is very important to keep an eye on, as mentioned before – If the chain links aren’t in a straight alignment with eachother, you can get in the water and simply attempt to twist the links back into a straight line with each other. If this doesn’t work, again, do not hesitate to call for service. It can’t be stressed enough how important regular service and maintenance truly is for such a high quality, specially designed machine like the Leisure Boat Lift.

Filed under: Uncategorized | Tagged: B.C., bc, boat lifts, boating, boatlift, dnr, hardware, how to lift a boat, idea, lbl, leisure boat lift, maintenance, manufacturing, marine, money, mooring, music, news, okanagan, service, single-side lifts, tournament boat, water safe | Leave a comment »